-

Telefon: +86 13423120627

-

E-post: [email protected]

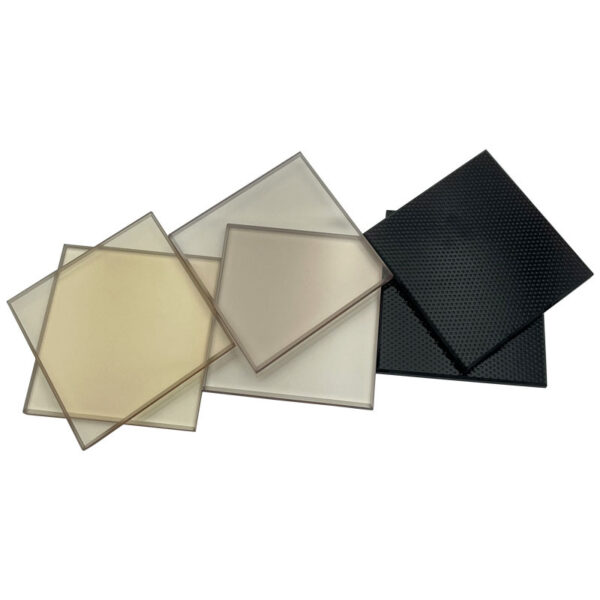

Toughened Glass

Toughened glass, also known as tempered glass, is a high-performance material engineered to offer exceptional strength and safety. Through a specialized tempering process involving extreme heating and rapid cooling, toughened glass becomes significantly stronger than ordinary glass, making it an ideal choice for a wide range of applications.

One of the standout features of toughened glass is its remarkable shatter resistance. When broken, it disintegrates into small, blunt pieces rather than sharp shards, greatly reducing the risk of injury. This safety characteristic makes toughened glass the preferred option for environments where safety is paramount, such as in automotive windows, shower doors, and storefronts.

In addition to its enhanced safety, toughened glass boasts impressive durability and heat resistance, capable of withstanding temperatures up to 470°F (245°C). This makes it suitable for use in fireplace doors, kitchen appliances, and other areas exposed to high heat. Its robust nature also ensures long-lasting performance, minimizing the need for frequent replacements and maintenance.

Toughened Glass: The Ultimate Safety Solution for Modern Architecture

Tempered glass sheets: The epitome of strength and safety in modern glass solutionsToughened glass, also known as tempered glass, is revolutionizing the world of architecture and interior design. This remarkable product offers unparalleled strength, safety, and versatility, making it an essential component in various applications. In this comprehensive guide, we’ll explore the ins and outs of toughened glass, its benefits, and why it’s becoming the go-to choice for both residential and commercial spaces.

What is Toughened Glass and How is it Made?

Toughened glass is a type of safety glass processed by controlled thermal treatments to increase its strength compared with normal glass. The process involves heating the glass to approximately 620°C and then rapidly cooling it. This creates a compressed outer layer and a tensile inner layer, resulting in a glass that is significantly stronger than standard annealed glass.The manufacturing process of toughened glass involves several steps:

- Cutting the glass to the desired size

- Examining for imperfections

- Washing and drying

- Heating in a furnace

- Rapid cooling (quenching)

This process creates a glass that is approximately four to five times stronger than regular glass, making it an ideal choice for various applications.

What Are the Key Benefits of Toughened Glass?

Toughened glass offers numerous advantages over standard glass:

- Enhanced Safety: When broken, toughened glass shatters into small, relatively harmless pieces instead of large, sharp shards.

- Increased Strength: It can withstand much higher loads and impacts compared to annealed glass.

- Thermal Resistance: Toughened glass can withstand temperature differences up to 250°C.

- Versatility: It can be used in a wide range of applications, from building facades to kitchen appliances.

How Does Toughened Glass Compare to Other Types of Glass?

Toughened glass stands out when compared to other glass types:

| Glass Type | Strength | Safety | Heat Resistance |

|---|---|---|---|

| Toughened Glass | ★★★★★ | ★★★★★ | ★★★★☆ |

| Annealed Glass | ★★☆☆☆ | ★☆☆☆☆ | ★★☆☆☆ |

| Laminated Glass | ★★★☆☆ | ★★★★★ | ★★★☆☆ |

| Float Glass | ★★☆☆☆ | ★☆☆☆☆ | ★★☆☆☆ |

As you can see, toughened glass excels in strength and safety, making it a superior choice for many applications.

What Are the Common Applications of Toughened Glass?

Toughened glass is incredibly versatile and finds use in numerous applications:

- Architectural Glass: Used in facades, windows, and doors

- Interior Design: Perfect for glass partitions, shower enclosures, and glass table tops

- Automotive Industry: Used in car windows and windshields

- Electronics: Smartphone screens and tablet displays

- Furniture: Glass shelves, tabletops, and cabinet doors

How Does Toughened Glass Enhance Safety in Buildings?

Safety is paramount in building design, and toughened glass plays a crucial role:

- It’s less likely to break under impact

- If it does break, it crumbles into small, dull-edged pieces, reducing the risk of injury

- It can withstand thermal stress better than regular glass

- It’s often used in safety-critical areas like balustrades and overhead glazing

What Are the Design Options Available with Toughened Glass?

Toughened glass offers a wide range of design possibilities:

- Colors: Available in various tints and colors

- Textures: Can be etched or patterned

- Shapes: Can be curved or bent into various shapes

- Sizes: Available in large formats for impressive architectural features

Designers and architects love the flexibility that toughened glass provides in creating stunning visual elements while maintaining safety standards.

How is Toughened Glass Maintained and Cleaned?

Maintaining toughened glass is relatively simple:

- Regular cleaning with mild soap and water

- Avoid abrasive cleaners that can scratch the surface

- Use a soft cloth or squeegee for drying

- Inspect regularly for any signs of damage

Proper maintenance ensures the longevity and performance of your toughened glass products.

Can Toughened Glass Be Cut or Drilled After Tempering?

One limitation of toughened glass is that it cannot be cut, drilled, or altered after the tempering process. Any modifications must be made before the glass is tempered. This is because the internal stresses created during tempering would cause the glass to shatter if altered afterward.

What Should You Consider When Choosing Toughened Glass?

When selecting toughened glass for your project, consider:

- The specific application and safety requirements

- The size and thickness needed

- Any special treatments (e.g., tinting, coating)

- The installation method

- Local building codes and regulations

Consulting with a glass supplier can help ensure you choose the right product for your needs.

How Does Toughened Glass Contribute to Energy Efficiency?

Toughened glass can be an excellent choice for energy-efficient buildings:

- It can be used in double or triple-glazed units for better insulation

- When tinted or coated, it can reduce solar heat gain

- Its strength allows for larger panes, maximizing natural light and reducing energy costs

By incorporating toughened glass into your building design, you can create a more sustainable and energy-efficient space.In conclusion, toughened glass is a remarkable product that offers a perfect blend of safety, strength, and style. Its versatility makes it suitable for a wide range of applications, from architectural marvels to everyday household items. As building regulations become stricter and safety concerns more prominent, the demand for toughened glass is only set to increase.Whether you’re a homeowner looking to upgrade your windows or an architect designing a cutting-edge building, toughened glass should be at the top of your list of materials to consider. Its benefits far outweigh those of standard glass, providing peace of mind along with aesthetic appeal.Key points to remember about toughened glass:

- It’s significantly stronger than regular glass

- It breaks into small, less harmful pieces when shattered

- It has excellent thermal resistance

- It’s versatile and can be used in various applications

- It contributes to building safety and energy efficiency

For more information on toughened glass and other custom glass solutions, don’t hesitate to reach out to a professional glass manufacturer. They can provide expert advice and help you choose the perfect glass product for your specific needs.