-

Telefono: +86 13423120627

-

E-mail: [email protected]

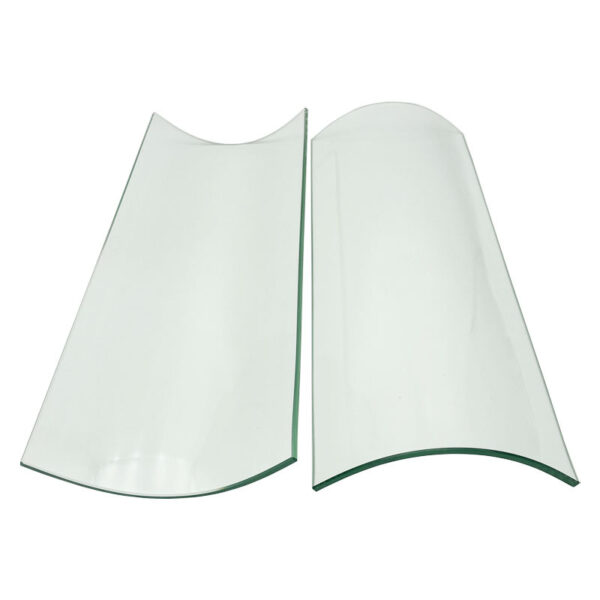

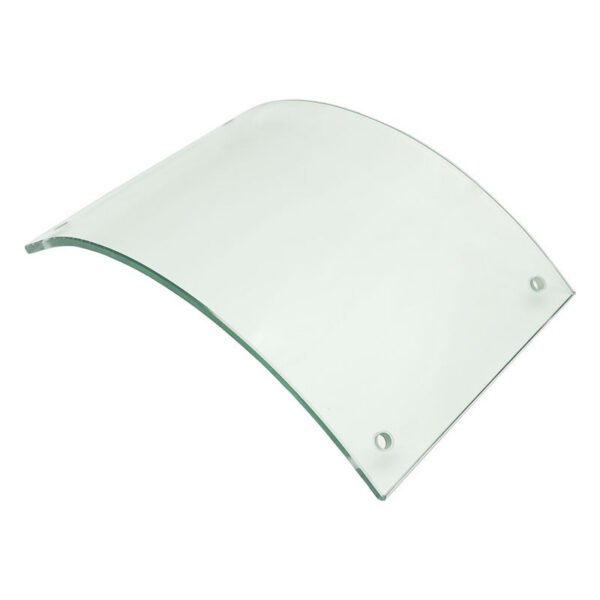

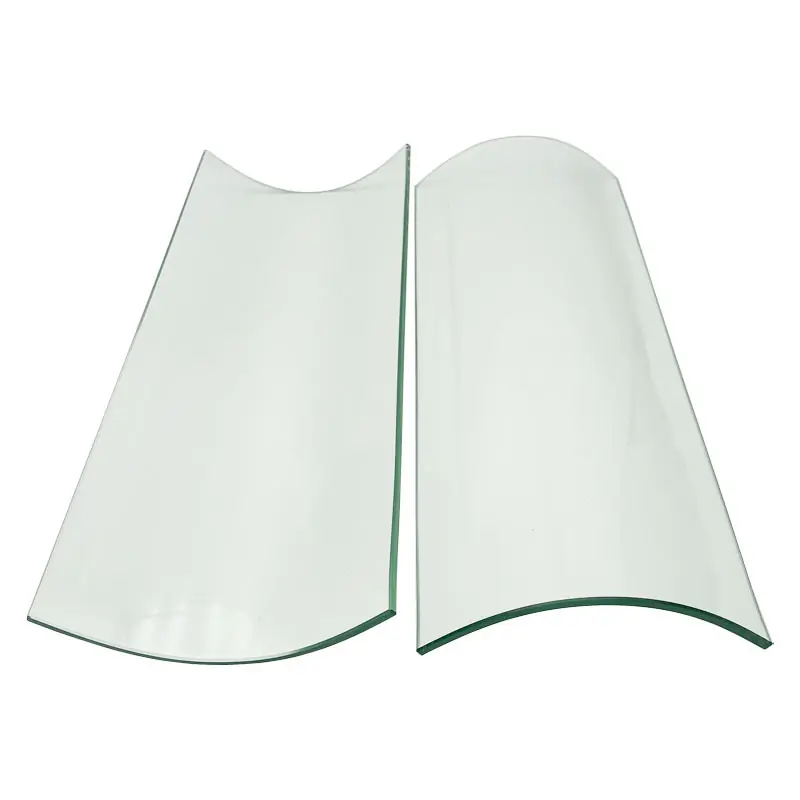

Vetro temperato curvo di sicurezza trasparente

Clear Safety Curved Tempered Glass: The Ultimate Solution for Modern Architecture

Clear safety curved tempered glass is a revolutionary product that combines aesthetics, durability, and safety in one elegant package. This innovative glass solution offers architects, designers, and homeowners the perfect blend of form and function, making it an ideal choice for a wide range of applications. From stunning curved facades to sleek shower enclosures, clear safety curved tempered glass is transforming the way we think about architectural glass.

Curved safety glass: A perfect blend of aesthetics and functionality

What is Clear Safety Curved Tempered Glass?

Clear safety curved tempered glass is a specialized type of glass that undergoes a unique manufacturing process to achieve its distinctive properties. This process involves heating float glass to its softening temperature and then carefully bending it into the desired curved shape. The glass is then rapidly cooled, creating a surface compression that significantly increases its strength and safety features.Some key characteristics of clear safety curved tempered glass include:

- Enhanced strength: Up to 4-5 times stronger than ordinary glass of the same thickness

- Improved safety: Breaks into small, rounded pieces when shattered, reducing the risk of injury

- Curved shape: Offers unique design possibilities and improved aesthetics

- Clarity: Maintains excellent optical clarity despite the curved form

How is Curved Tempered Glass Made?

The process of making curved tempered glass involves several steps:

- Glass selection: High-quality float glass is chosen as the base material.

- Cutting and shaping: The glass is cut to size and shaped according to the desired specifications.

- Heating: The glass is heated in a furnace to its softening temperature (around 600°C).

- Bending: While hot, the glass is carefully bent into the desired curved shape using specialized molds.

- Rapid cooling: The bent glass is quickly cooled using air jets, creating surface compression.

- Quality control: The finished product undergoes rigorous testing to ensure it meets safety and quality standards.

This complex process requires expertise and precision, which is why it’s crucial to choose a reputable custom tempered glass manufacturer for your curved glass needs.

What Are the Benefits of Using Clear Safety Curved Tempered Glass?

Clear safety curved tempered glass offers numerous advantages over traditional flat glass or ordinary curved glass:

- Enhanced aesthetics: The smooth, flowing lines of curved glass add a touch of elegance and sophistication to any space.

- Improved safety: The tempered glass is much stronger than annealed glass and breaks into small, less dangerous pieces if shattered.

- Versatility: Can be used in a wide range of applications, from architectural facades to interior design elements.

- Durability: Resists scratches, impacts, and temperature changes better than standard glass.

- Energy efficiency: When used in insulated glass units, curved tempered glass can contribute to improved thermal performance.

Where Can Clear Safety Curved Tempered Glass Be Used?

The applications for clear safety curved tempered glass are virtually limitless. Some popular uses include:

- Architectural facades and curtain walls

- Schermi doccia in vetro curvo

- Balustrades and glass railings

- Display cases and retail showcases

- Cornici in vetro curvo

- Furniture pieces, such as glass tables with curved edges

- Automotive and transportation applications

How Does Clear Safety Curved Tempered Glass Compare to Other Glass Types?

To better understand the advantages of clear safety curved tempered glass, let’s compare it to other common glass types:

| Glass Type | Strength | Safety | Aesthetics | Versatility |

|---|---|---|---|---|

| Clear Safety Curved Tempered | High | High | Excellent | High |

| Flat Tempered | High | High | Good | Moderate |

| Annealed Glass | Low | Low | Good | Low |

| Laminated Glass | Moderate | High | Good | Moderate |

As you can see, clear safety curved tempered glass offers an optimal combination of strength, safety, aesthetics, and versatility, making it an excellent choice for a wide range of applications.

What Are the Design Possibilities with Clear Safety Curved Tempered Glass?

The unique properties of clear safety curved tempered glass open up a world of design possibilities:

- Create stunning, seamless curved facades for modern buildings

- Design elegant, frameless shower enclosures with curved glass panels

- Craft eye-catching display cases and retail showcases

- Develop innovative furniture pieces with curved glass elements

- Incorporate curved glass into balustrades and railings for a sleek, modern look

Designers and architects can push the boundaries of traditional glass applications, creating spaces that are both visually striking and functionally superior.

How to Choose the Right Curved Tempered Glass for Your Project?

When selecting curved tempered glass for your project, consider the following factors:

- Curvature radius: Determine the desired curve for your application

- Glass thickness: Choose based on the size and load requirements of your project

- Glass type: Consider options like low-iron glass for improved clarity

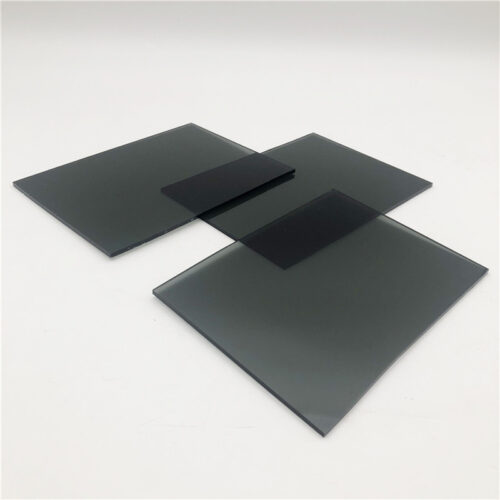

- Coatings and treatments: Explore possibilities such as reflective coatings or customized safety tempered tinted glass

- Insulation requirements: Decide if you need single-pane or insulated glass units

- Safety standards: Ensure the glass meets relevant safety codes and regulations

Consulting with a reputable curved tempered glass supplier can help you make the best choice for your specific needs.

What Are the Maintenance Requirements for Clear Safety Curved Tempered Glass?

One of the advantages of clear safety curved tempered glass is its relatively low maintenance requirements. However, to keep it looking its best:

- Clean regularly with a mild, non-abrasive glass cleaner

- Avoid using harsh chemicals or abrasive materials that could scratch the surface

- Inspect periodically for any signs of damage or wear

- Address any chips or cracks promptly to maintain safety and integrity

Proper maintenance will ensure your curved tempered glass retains its beauty and functionality for years to come.

How Much Does Clear Safety Curved Tempered Glass Cost?

The cost of clear safety curved tempered glass can vary significantly depending on several factors:

- Size and complexity of the curve

- Glass thickness and type (e.g., standard float glass vs. low-iron glass)

- Quantity ordered

- Additional treatments or coatings

- Shipping and installation requirements

While curved tempered glass is generally more expensive than flat tempered glass, its unique properties and aesthetic appeal often justify the investment. For accurate pricing, it’s best to consult with a custom curved glass manufacturer who can provide a quote based on your specific requirements.

Conclusion: Why Choose Clear Safety Curved Tempered Glass?

Clear safety curved tempered glass represents the pinnacle of modern glass technology, offering a perfect blend of aesthetics, safety, and durability. Its unique properties make it an ideal choice for a wide range of applications, from stunning architectural features to practical interior design elements.By choosing clear safety curved tempered glass, you’re investing in a product that not only enhances the visual appeal of your space but also provides superior safety and performance. Whether you’re an architect designing a cutting-edge building facade or a homeowner looking to upgrade your shower enclosure, curved tempered glass offers unparalleled versatility and style.As the demand for innovative and visually striking glass solutions continues to grow, clear safety curved tempered glass is poised to play an increasingly important role in shaping the built environment of the future. Embrace the curve and discover the transformative power of this remarkable glass product.